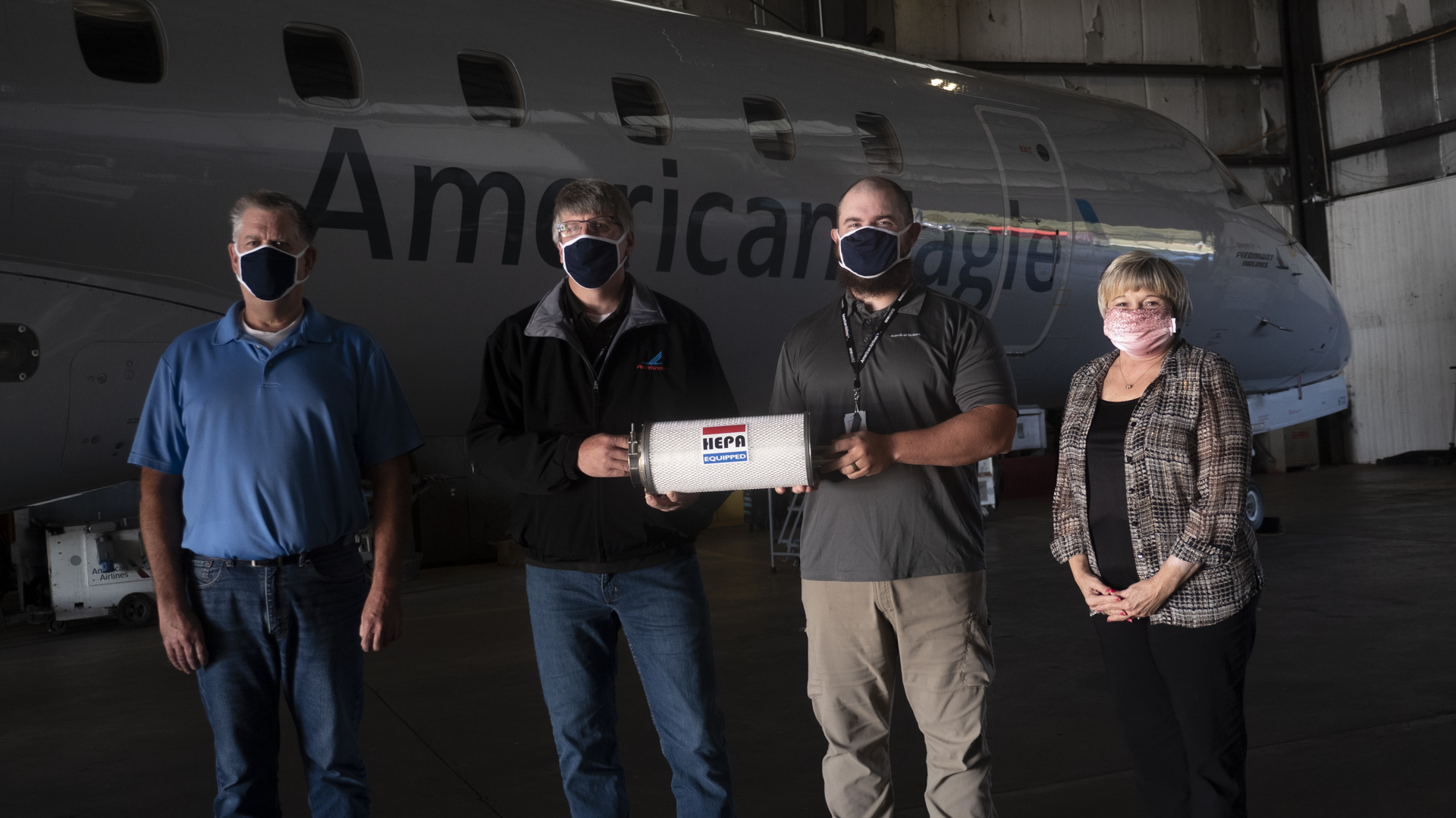

Piedmont adds HEPA filtration to Embraer 145 fleet

When COVID hit the United States back in March, passengers started asking about the air quality in American Airlines aircraft. While most American Airlines fleet types had HEPA (High Efficiency Particle Air) filters on board their aircraft, Piedmont’s Embraer 145s did not. That sparked Piedmont’s innovative spirit. “Pre-COVID, our E145s had a large particle screen but not a small particle filter or one of HEPA quality,” said Ross Peterson, Director of Engineering and Reliability. “I had an idea to utilize and modify a previous Piedmont designed Dash-8 recirculation fan filter to create a HEPA filter,” said Ross. “This is the kind of innovation we need to make sure Piedmont is the best American Airlines regional partner.” After five months of research, testing and FAA approval, the first HEPA filtration modification was installed on aircraft N637AE.

HEPA technology is used in hospitals and medical facilities around the world, helping keep medical environments clear of bacteria and viruses while providing clean air. The HEPA filters in use on American’s fleet capture at least 99.97% of airborne microbes by circulating the cabin air once every two to four minutes.

Each E145 will have three filters that filter air every three minutes. The filtration system is located under the floor and out of view of passengers and crew.

With Piedmont’s original workhorse, the Dash-8, retired and Ross’ previous knowledge of installing filter systems, he was able to modify the Dash-8 filters for use on the E145. “A good amount of tooling and raw material used to build Dash-8 equipment was still available and was used to create prototypes,” said Ross.

“Embraer offered to develop a system for the 145s but they estimated it would take two to three years with an unknown final price,” said Ross. “We couldn’t wait that long. The modification we designed was cost efficient and installed in one of our planes only five months after concept.”

Ross credits the success of this program to the hard work of the Reliability and Engineering, Maintenance, Quality Control, and Purchasing teams to get this done.

Piedmont received FAA approval on October 6 through a Supplemental Type Certificate (STC) and Major Alteration approval to perform the modification on Piedmont’s E145 fleet.